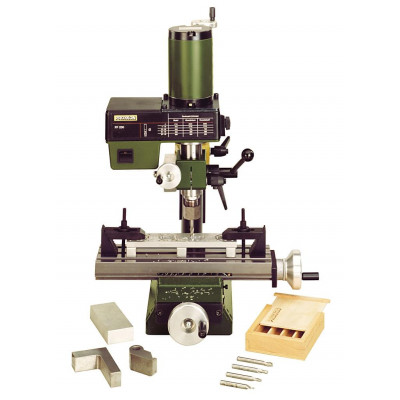

Proxxon Draaibank PD 400 CNC 24500

- Art. Nr.: PRX-24500

€4.399,-

Excl. BTW: €3.635,54

100 dagen bedenktijd

Productomschrijving

Afstand tussen de centers 400 mm. Centerhoogte 85 mm. Center hoogte boven support 58 mm.

Voor bewerking van staal, messing, aluminium en kunststof.

Voordwars, langs draaien, conus draaien en draadsnijden.

Met de diverse accessoires, kunt u ook boren, frezen en groeven.

Machinebed: Gemaakt van hoge kwaliteit gietstaal.

Kruis geribbeld met brede benen, gepolijste prismavoering.

Voor trillingvrij bewerken, zelfs bij zwaardere belastingen.

Achterzijde met flens en schroefgaten voor de bevestiging van de boor en freesmachine PF 400.

Bedekte loodschroef.

Spindel: Van gegoten aluminium.

Oversized spindel met twee verstelbare kogellagers en MC 3 adapters chuck-kant.

Spindelboring 20,5 mm.

Rondloop zonder materiaal 1/100 mm.

Draaischakelaar voor de aansluiting van de automatische voeding (optie 0,07 en 0,14 mm/U).

Glij- en schroefspindel met trapeziumvormige schroefdraad (12 x 1,5 mm).

Losse kop: Van gegoten aluminium.

Pinole Ø 24 mm, instelbaar tot 40 mm.

Met mm schaalverdeling. Deze meelopende center met MC 2 en 10 mm boorkop (B 12 - Opname/MC 2).

Support: Slee bed uit gegoten zink.

Dwarsslee (85 mm verstelbaar) en bovenste schuif (aanpasbaar 52 mm) gemaakt van staal.

Bovenste slee voor kegeldraaien draaibare (instelbaar tot 45 °).

Met meervoudige stalen houder en twee stalen elementen voor snelle veranderingen en eenvoudig in hoogte verstelbaar.

Draaigereedschap 10 x 10 mm.

Aandrijving: Krachtige condensatormotor voor twee snelheden

En een extra drie-traps riemaandrijving.

Spiltoerentallen op

-Niveau 1: 80 – 330 – 1.400/min.

-Niveau 2: 160 – 660 en 2.800/min.

Klauwplaat: Hoogwaardige kwaliteit 3-klauwplaat volgens DIN 6386, klasse 1 (rondloop tolerantie 0,04 mm).

Spanbereik van omkeerbare bekken 3 – 100 mm.

Met boorkopbescherming en veiligheidsuitschakeling.

Handwiel: Gemaakt van aluminium, met op 0 instelbare schaalverdeling.

Voor kruis en de bovenste slee: 1 bar = 0,025 mm. 1 U = 1 mm.

Voor losse kop en lood schroef: 1 bar = 0,05 mm. 1 U = 1,5 mm.

Support–snelle fijnafstelling:

Dankzij het grote wiel op een draadeind bevestigd aan het bed.

Draadsnij inrichting: Voor links en rechtse draad.

Met verwisselbare wielen voor 19 verschillende spoed (metrisch):

0,2 – 0,25 – 0,3 – 0,35 – 0,4 – 0,45 – 0,5 – 0,6 – 0,7 – 0,75 – 0,8 – 0,9 – 1 – 1,25 – 1,5 – 1,75 – 2 – 2,5 – 3 mm.

Ook voor inch draad 10 – 48 versnelling.

Technische gegevens:

Spanning: 230 V. 50/60 Hz.

Afmetingen: L 900, D 400, H 300 mm.

Gewicht ca. 45 kg.

Motor vermogen 870 W, uitgangsvermogen 550 W.

Toerentallen van 1.400 / 2.800/min.

NO 24 400

Draaimachine PD 400/CNC

Ook deze machine wordt compleet met besturingseenheid en gebruiksvriendelijke software geleverd (WINDOWS®). As-aandrijving door twee stappenmotoren en kogelomloopspillen. De mechanische opbouw is gelijk aan die van de PROXXON draaimachine PD 400 (zie blz. 60 /61).

NO 24 500

LET OP IN VERBAND MET HET GEWICHT ALLEEN LEVERBAAR NA OVERLEG!

Verzendkosten is afhankelijk van de locatie, dit artikel komt niet in aanmerking voor gratis verzending!

Voor levering buitenland neem eerst contact op!

Specificaties

Andere opties

Afstand tussen de centers 150 mm. Centerhoogte 55 mm. Centerhoogte boven support 33 mm.Voor dwars-, langs-, uitdraaien, conus..

€499,-

Excl. BTW:€412,40

Dwars-, langs- en conusdraaien, draadsnijden. Voor de bewerking van staal, messing, aluminium en kunststof.

Opbouwflens voor..

€1.199,-

Excl. BTW:€990,91

Maakt van uw draaibank PD 250/E en PD 400 is een compleet bewerkingscentrum.Inclusief kolom (35 x 400 mm), montageflens ..

€659,-

Excl. BTW:€544,63

Boorkop 360° zwenkbaar (met gradenindeling).

Booras met boordiepte-indicatie door schaalring (1 deel-streep = 1 mm).

Krac..

€899,-

Excl. BTW:€742,98

Afstand tussen de centers 400 mm. Centerhoogte 85 mm. Center hoogte boven support 58 mm.Voor bewerking van staal, messin..

€2.899,-

Excl. BTW:€2.395,87

Met grote multifunctionele display, 3 glazen meetlatten (incl. sensor) en bevestigingsmiddelen.Nuttig voor herhaalde bew..

€779,-

Excl. BTW:€643,80

Snijplaathouder met snijplaten

Voor buitendraad M 3 – 4 – 5 – 6 – 8 en 10 mm.

Met inspan as Ø 10 mm voor bevestiging van..

€74,95

Excl. BTW:€61,94

Machinehouder voor het rondslijpen op draaibanken

Gemaakt van staal met 20 mm MICROMOT systeem.

Voor een nauwkeurige klemm..

€14,95

Excl. BTW:€12,36

Downloads

Lagere prijs?

Wilt u ook altijd de beste prijs?

Wij bieden onze klanten eerlijke prijzen en controleren regelmatig onze prijzen met andere aanbieders. Zo kunnen we vaak de laagste prijs bieden.

Vind u toch een lagere prijs binnen Nederland bij een fysieke winkel stuur ons dan een bericht en wij kijken onze prijs voor u na.

Als we dezelfde prijs kunnen aanbieden ontvangt u van ons de nieuwe prijs voor het product.

Spelregels

1. Alleen reguliere prijzen bij andere winkels in Nederland doen hierin mee.

2. De aanbieder dient minstens 1 fysieke winkel met showroom en servicebalie te hebben in Nederland

3. Eventuele verzendkosten worden meegenomen in de prijs van de andere winkel

4. Aanbiedingen zijn uitgesloten van deelname.

5. Prijzen dienen openbaar zichtbaar te zijn

6. Het product is bij de andere winkel vanuit voorraad leverbaar en staat ook zodanig openbaar vermeld.

7. Niet van toepassing met terugwerkende kracht

8. Prijsfouten zijn uitgesloten van deelname

9. Producten dienen identiek te zijn.

Vul onderstaand formulier in

* Verplichte velden

Reviews

Gemiddelde van 0 reviews

Beoordeling per onderdeel

-

50 reviews

-

40 reviews

-

30 reviews

-

20 reviews

-

10 reviews

U kunt een review plaatsen

Sorteren op

Rapporteer deze review.

Tags: proxxon,

gereedschap,

tools,

draaibank,

fijndraaimachine,

lathe,

precision,

pd 400,

pd400,

pd,

24500,

4006274245006