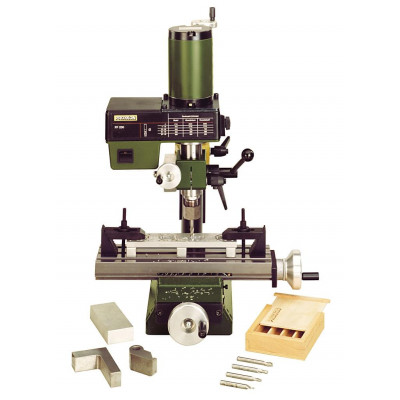

Proxxon Fijnfrees FF 500/BL CNC 24360

- Art. Nr.: PRX-24360

€5.199,-

Excl. BTW: €4.296,69

100 dagen bedenktijd

Nooit meer leverbaar

Productomschrijving

Fijnfrees FF 500/BL

Met een traploos toerental voor 200 – 4.000/min bij een hogere precisie (nauwkeurigheid 0,05 mm). Met digitale toerental aanduiding. De uitwendige regeling door rotorpolen en toerentalsensoren garanderen een hoog draaimoment met het instellen van een frees onder het toerentalbereik. Massief zuil met profielgeleiding. Freeskop naar 90° links en rechts draaibaar (met gradenindeling). De pinole is klembaar en voor het aanpassen van de fijnvoeding (zie hieronder). Werktuigafname door meerdere spantangen die erbij zitten Type ER 20 (EIN 6499-B): 6 – 8 – 10 en 12 mm (van elk 1 stuk). Hoogeverstelling van de freeskop d.m.v. een knop. Massieve kruistafel uit staal met 3 T-gleuven (12 x 6 x 5 mm). Alle 3 met schaalring (1 U = 2 mm).

Technische gegevens: 230 V. 400 W. 50/60Hz. Spindeltoeren 200 – 4.000/min. Uitlading 125 mm. Pinole knop 30 mm. Zuil 120 x 100 x 430 mm. Tafel 400 x 125 mm. Verticaal (Z-as) 220 mm, horizontaal (X-as) 310 mm, diepte (Y-as) 100 mm. Afmetingen: H = 750 mm, B = 550 mm, L = 550 mm. Gewicht circa 47 kg.

NO 24 350

Fijnfreesmachine FF 500/BL-CNC

Compleet met besturings eenheid en gebruiksvriendelijke software

WINDOWS®.

Dubbelle rollager kogelomloopspillen, bij alle drie assen en drie krachtige

stappenmotoren. Grote verplaatsingsweg; X as ca. 290 mm, Y as ca.

100 mm, Z as ca. 200 mm. De mechanische opbouw is gelijk aan die van

de fijnfreesmachine FF 500 NO 24 360

Fijnfrees FF500/BL-CNC-ready

Zoals hier beschreven, maar zonder besturing en software. Aansluiting met 3

norm-stekkers (SUB-D 9POL).

NO 24 364

Opmerking: Spanklemmen, frees en het werkstuk behoren niet tot de standaard uitrusting.

Specificaties

Andere opties

Voor het afschuinen, herstellen van sleuven, cirkels en andere profielen.Voor het vervaardigen van schilderijlijsten en om ui..

€189,-

Excl. BTW:€156,20

Met stappenmotoren voor de X-as (lengte), Y (breedte) en Z (hoogte) door middel van handwielen.Interessant voor gebruike..

€619,-

Excl. BTW:€511,57

Geschikt voor extreem kleine frezen.

Stevige machinevoet gemaakt van gietijzer, verticale geleiding en kruistafel.

Alle a..

€299,-

Excl. BTW:€247,11

Afstand tussen de centers 150 mm. Centerhoogte 55 mm. Centerhoogte boven support 33 mm.Voor dwars-, langs-, uitdraaien, conus..

€499,-

Excl. BTW:€412,40

Boorkop 360° zwenkbaar (met gradenindeling).

Booras met boordiepte-indicatie door schaalring (1 deel-streep = 1 mm).

Krac..

€899,-

Excl. BTW:€742,98

Afstand tussen de centers 400 mm. Centerhoogte 85 mm. Center hoogte boven support 58 mm.Voor bewerking van staal, messin..

€2.899,-

Excl. BTW:€2.395,87

Met grote multifunctionele display, 3 glazen meetlatten (incl. sensor) en bevestigingsmiddelen.Nuttig voor herhaalde bew..

€779,-

Excl. BTW:€643,80

Set spantangen type ER 20 (DIN 6499-B)

Voor de freesmachine PF 400 ( vanaf productie nr. 401-10910 ) en FF 500 ( vanaf produ..

€59,95

Excl. BTW:€49,55

Downloads

Lagere prijs?

Wilt u ook altijd de beste prijs?

Wij bieden onze klanten eerlijke prijzen en controleren regelmatig onze prijzen met andere aanbieders. Zo kunnen we vaak de laagste prijs bieden.

Vind u toch een lagere prijs binnen Nederland bij een fysieke winkel stuur ons dan een bericht en wij kijken onze prijs voor u na.

Als we dezelfde prijs kunnen aanbieden ontvangt u van ons de nieuwe prijs voor het product.

Spelregels

1. Alleen reguliere prijzen bij andere winkels in Nederland doen hierin mee.

2. De aanbieder dient minstens 1 fysieke winkel met showroom en servicebalie te hebben in Nederland

3. Eventuele verzendkosten worden meegenomen in de prijs van de andere winkel

4. Aanbiedingen zijn uitgesloten van deelname.

5. Prijzen dienen openbaar zichtbaar te zijn

6. Het product is bij de andere winkel vanuit voorraad leverbaar en staat ook zodanig openbaar vermeld.

7. Niet van toepassing met terugwerkende kracht

8. Prijsfouten zijn uitgesloten van deelname

9. Producten dienen identiek te zijn.

Vul onderstaand formulier in

* Verplichte velden

Reviews

Gemiddelde van 0 reviews

Beoordeling per onderdeel

-

50 reviews

-

40 reviews

-

30 reviews

-

20 reviews

-

10 reviews

U kunt een review plaatsen

Sorteren op

Rapporteer deze review.

Tags: proxxon,

gereedschap,

tools,

boren,

frezen,

boorkop,

freesinrichting,

ff 500,

ff500,

cnc,

cnc-ready,

24320,

24350,

24360,

4006274243606